Rongxu tell you CNC machine processing matters needing attention

Hits:2939

Hits:2939

Date:2020-09-05

Date:2020-09-05

With the comprehensive promotion of Made in China 2025, China's manufacturing industry is developing rapidly, and CNC, as one of the important forms of manufacturing, is also being known by more and more people. So CNC machine tool processing are what matters we should pay attention to in the operation? Rongxu xiaobian tells you below.

1, machine tool downtime for more than eight hours, machine tool need heat machine 15 minutes before processing work, heat machine pay attention to whether the tool and workpiece interference.

2, before running the processing, to check whether the workpiece, fixture and tool has been clamped firmly.

3. After the machine is started, the z-axis of the machine shall be returned to zero first, and then the XY axis shall be returned to zero. During the return to zero process, pay attention to the relative position of each axis of the machine to avoid collision during the return to zero process.

4, according to the provisions of the process of processing, do not arbitrarily increase the knife, cutting speed, do not exceed the standard, overload, overweight equipment.

5. The cutting produced during processing should be blown off with an air gun. It is forbidden to touch the knife toughness and the workpiece by hand during processing.

6, before shutdown, ensure that XY axis stop in the center position, Z axis back to zero.

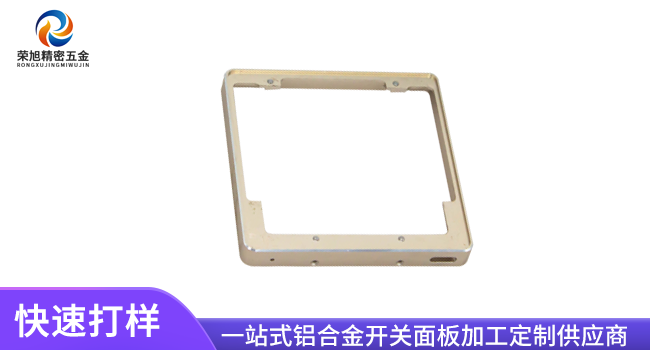

Dongguan Rongxu Precision Hardware Co., Ltd. is a one-stop CNC aluminum alloy processing customized services manufacturers, focusing on aluminum alloy shell, aluminum alloy frame, aluminum alloy panel, aluminum alloy parts and other precision parts, excellence, quality for the first of our work style; Urgent customers urgent, for customers think is our way of hospitality, won the trust and recognition of the majority of customers.