free Customization 0769-83716856

Service Hotline:0769-83716856

Phone:18925513856

Email:18925513856@163.com

Address:Room 103, Building 1, No. 9 Xin'an Xingwang 4th Road, Changan Town, Dongguan City, Guangdong Province

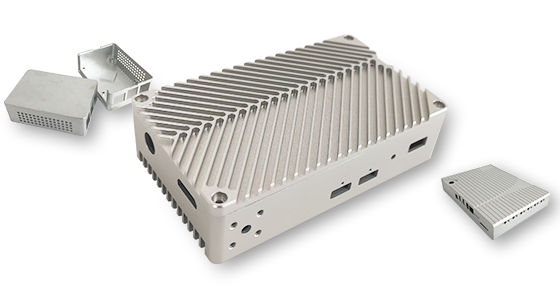

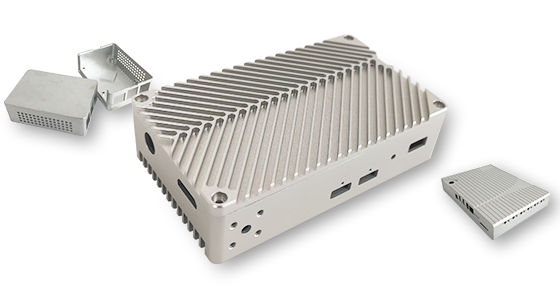

Specific tensile strength, yield strength, ductility and corresponding processing hardening rate dominate the change of allowable deformation. This product has a wide range of applications such as: mobile power supply, adapter, controller, vehicle shell CPS/ CPRS shell, inverter shell CPU radiator shell, power shell, electronic communications, power communications, medical equipment, controller chassis and so on. The size can be customized.

18925513856

Characteristics of aluminum shell processing:

1. Corrosion resistance.

The density of aluminum shell is only 2.7g 7.83g/ cm3,8.93g/ cm3 cm3, which is about the density of steel, copper or brass.

Aluminum exhibits excellent corrosion resistance in most environmental conditions, including air, water (or salt water), petrochemistry, and many chemical systems.

2. Electrical conductivity.

Aluminum shell processing is often selected because of its excellent electrical conductivity.

On the basis of equal weight, the electrical conductivity of aluminum is nearly twice that of copper.

3. Thermal conductivity.

The thermal conductivity of aluminum alloy is about 50-60% of that of copper, which is beneficial to the manufacture of heat exchangers, evaporators, heating appliances, cooking utensils, as well as cylinder heads and radiators of cars.

4. Non-ferromagnetism.

Aluminum profiles are non-ferromagnetic, which is an important characteristic for the electrical and electronic industries.

Aluminum profiles cannot be ignited spontaneously, which is important for applications involving loading, unloading or contact with flammable and explosive materials.

5. Machinability.

The machinability of aluminum shell is excellent.

In all kinds of deformed aluminum alloy and cast aluminum alloy, as well as in various states after the production of these alloys, the machining properties change greatly, which requires special machine tools or technology.

6. Formability.

Specific tensile strength, yield strength, ductility and corresponding processing hardening rate dominate the change of allowable deformation.

Aluminum shell

Mobile video terminal shell

Face recognizer housing